Njikọ nke Alkyl polyglycoside carbonates

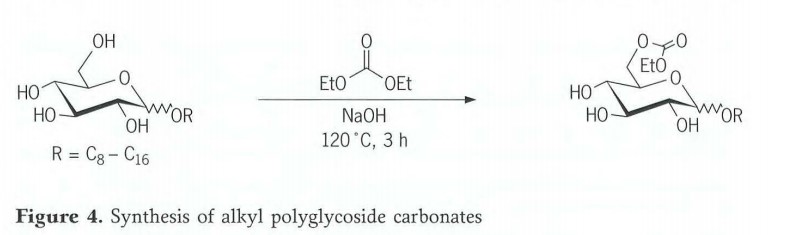

A kwadebere carbonates alkyl polyglycoside site na transesterification nke alkyl monoglycosides na diethyl carbonate (Nyocha 4).Maka ọdịmma nke ịgwakọta nke ọma nke ndị na-eme ihe, ọ egosila na ọ bara uru iji diethyl carbonate karịa ka ọ na-eje ozi ma dị ka akụkụ transesterification na ihe mgbaze.2Mole-% nke 50% sodium hydroxide ngwọta na-agbakwunyere dropwise na ngwakọta a na-akpali akpali na gburugburu 120 ℃. Mgbe 3hours n'okpuru reflux, mmeghachi omume ngwakọta na-ekwe ka ajụkwa 80 ℃ na neutralized na 85% phosphoric acid.A na-ewepụ carbonate diethyl ngafe na vacuo.N'okpuru ọnọdụ mmeghachi omume ndị a, a na-edozi otu hydroxyl otu ọkacha mma.Oke nke ihe fọdụrụ na ngwaahịa na 1: 2.5: 1 (monoglycoside: Monocarbonate: Polycarbonate).

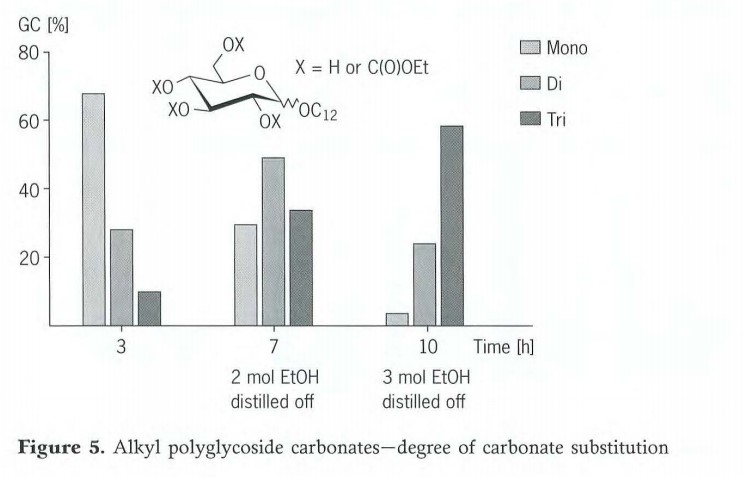

E wezụga monocarbonate, a na-emepụtakwa ngwaahịa ndị nwere oke ngbanwe dị elu na mmeghachi omume a.Enwere ike ịchịkwa ogo nke mgbakwunye carbonate site na njikwa ọkachamara nke mmeghachi omume.Maka otu C12 monoglycoside, a na-enweta nkesa nke mono-, di- na tricarbonate nke 7: 3: 1 n'okpuru ọnọdụ mmeghachi omume nke akọwapụtara (Fig 5).Ọ bụrụ na oge mmeghachi omume na-abawanye ruo 7hours ma ọ bụrụ na 2moles nke ethanol na-ekpochapụ n'oge ahụ, isi ngwaahịa bụ C.12 monoglycoside dicarbonate.Ọ bụrụ na ọ na-abawanye na 10hours na 3moles nke ethanol na-ekpochapụ, isi ngwaahịa emecha nweta bụ tricarbonate.Ogo nke mgbakwunye carbonate na ya mere nguzozi hydrophilic / lipophilic nke ogige alkyl polyglycoside nwere ike gbanwee nke ọma site na mgbanwe nke oge mmeghachi omume na olu distillate.

Oge nzipu: Mar-22-2021